The advantages of replacing artificial vision inspection with machine vision inspection system become more and more obvious in the higher degree of automation. For example, in the inspection of PCB SMT patches, welded finished products and semi-finished products in the electronic industry, the traditional manual inspection requires more employees to carefully and carefully inspect, and there are differences in personnel safety and product quality depending on the professional level and training level of personnel. On the other hand, there are many soldering points and small and precise components on PCB, which leads to high labor intensity and low detection efficiency, and is easily influenced by personal subjective factors, which greatly limits the production efficiency and the control of product quality. With the development of industrialization, manufacturing tends to be multi-functional, intelligent and miniaturized. As an important precision component in electronic products, the components used on PCB are more sophisticated and have higher requirements. Then, it is very important to control the quality of inspection.

In order to reduce the production cost, improve the quality control of products and meet the production qualification rate of enterprises, it is necessary to use machine inspection system instead of manual inspection.

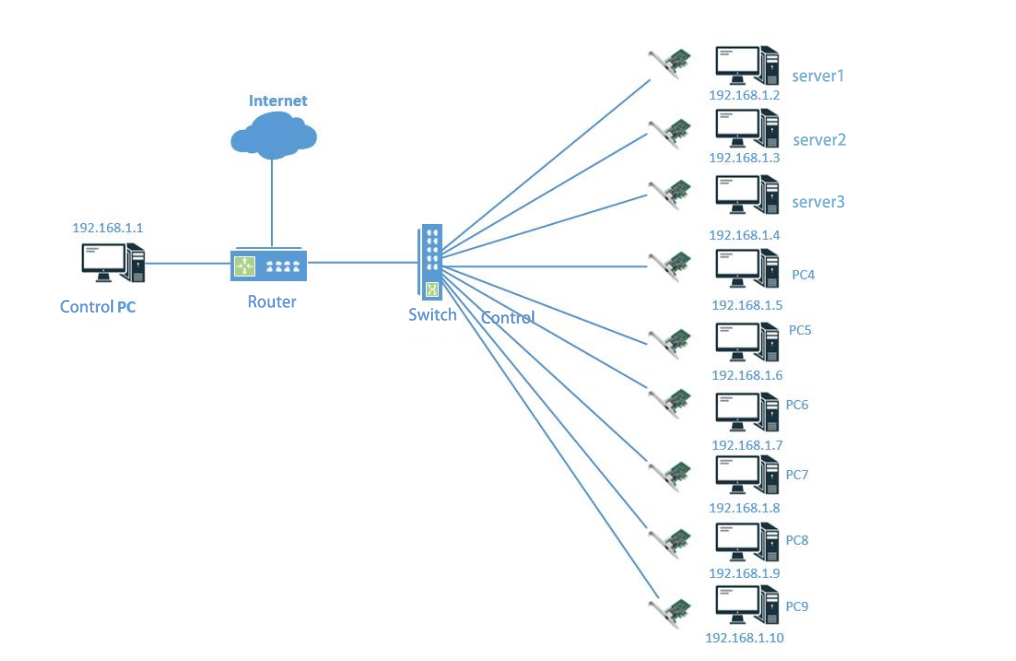

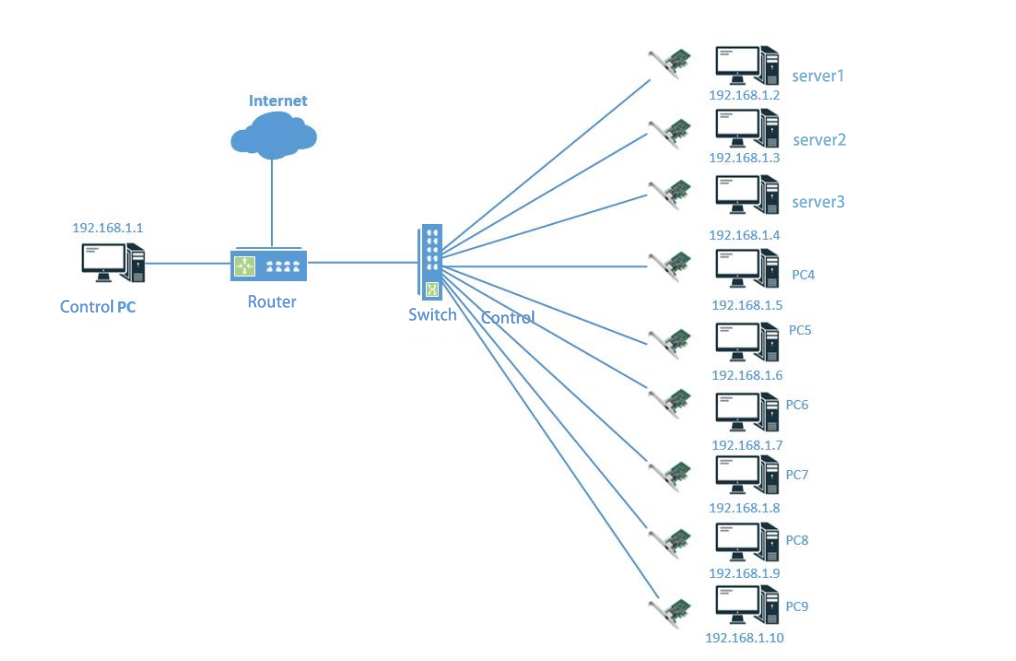

In terms of hardware, it can be built based on various hardware platforms. Industrial computer provides powerful computing power support for vision inspection schemes. In terms of software system, the intelligent vision system platform builds channels for data collection, transmission and processing, which not only meets the traditional visual requirements such as component inspection, identification and positioning on PCB, but also realizes the optimization and acceleration of vision system algorithms, and realizes enterprise productivity growth, efficient processing and so on.

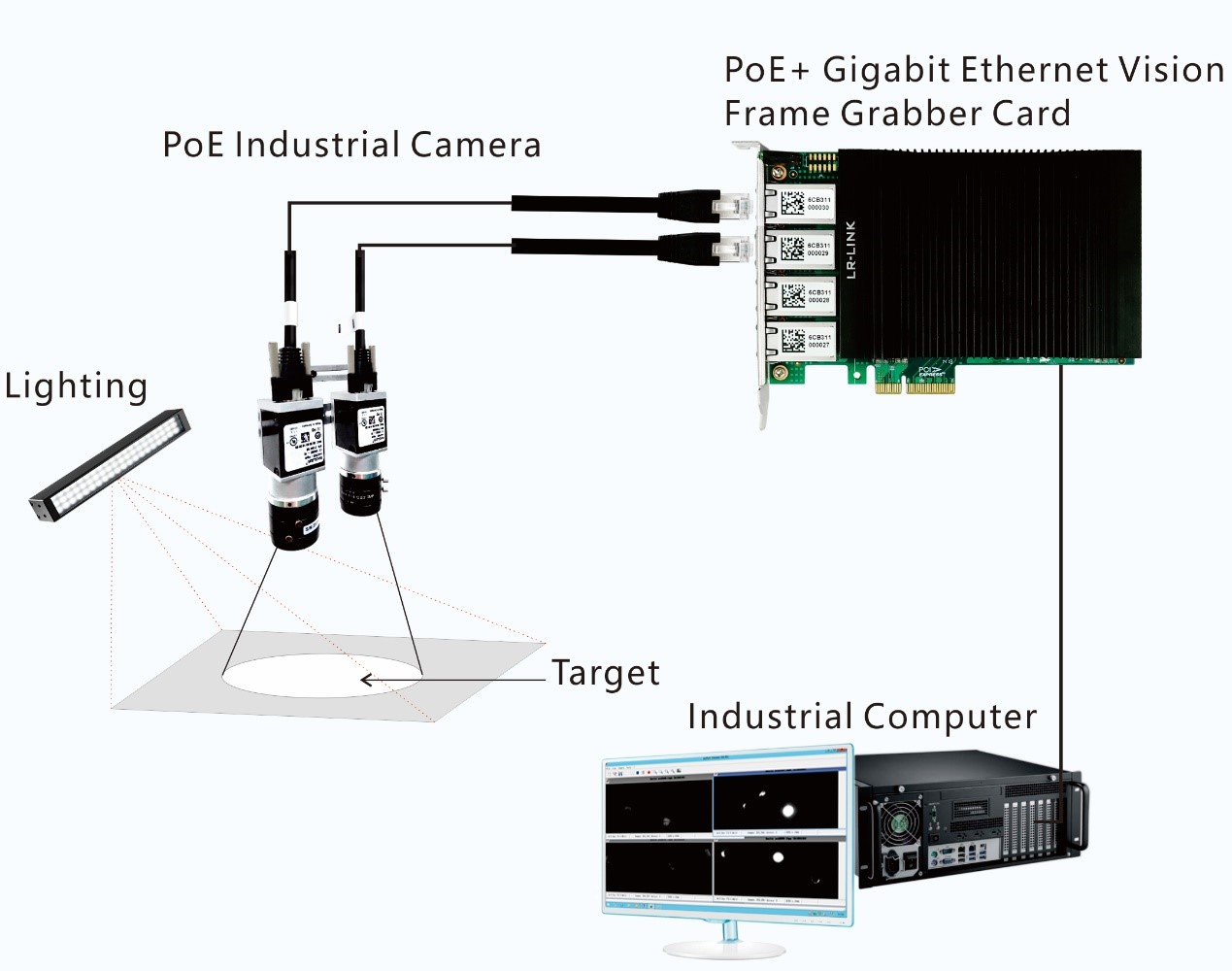

According to different detection schemes adopted for different detection requirements, the workflow of intelligent vision system adopts PoE network card (Gigabit PoE network card or 10 Gigabit PoE network card) installed on industrial computer to transfer the data collected from industrial camera to vision program for analysis and calculation. So as to meet that requirement of on-site multi-demand detection.

The inspection process is as follows: after the product to be inspected reaches the inspection position, the industrial camera completes the image acquisition of the PCB product to be inspected, and transmits the image information to the computer through Ethernet. The computer program will carry out content inspection on the PCB and components on the board, such as the presence or absence of components (plug-ins), positive and negative detection of components (plug-ins), component (plug-in) color detection, component (plug-in) direction detection, wire color detection, terminal seat color detection, etc. And send the processed results to the designated end of the customer, and make specified actions, such as rejection and alarm.

At present, including the electronic industry, the production change of enterprises with intelligent manufacturing as the core is affecting all walks of life, and industrial intelligent manufacturing will be the key to drive the future industrial system. With the support of intelligent vision system, the rapid deployment of production capacity and flexible and efficient manufacturing can help the rapid development of intelligent manufacturing.