Application Background

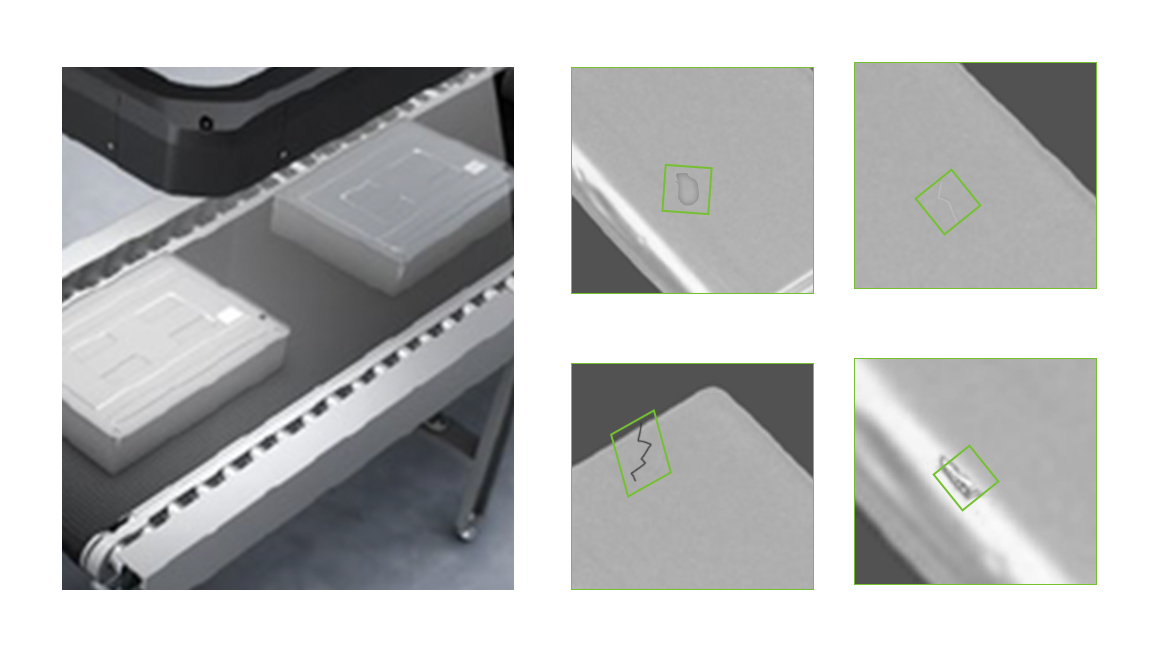

The lithium battery market is becoming increasingly mature, and power lithium batteries have become a new engine driving the rapid development of the entire lithium battery industry. However, during the production process of lithium batteries, various defects in appearance inevitably occur, which affect the quality of the product and the assembly of the battery pack and even cause serious quality hazards. Therefore, detecting appearance defects of lithium batteries is a very important part of lithium battery manufacturing

Application Challenge

However, the traditional manual visual inspection method has high missed detection rates and low efficiency and cannot meet the needs of automated and rapid production. Machine vision is applied to the lithium battery detection process to improve the speed and accuracy of lithium battery detection. However, during the detection process, it is often easy for some defects to not be truly detected due to frame loss, packet loss, etc., thus affecting the quality of the product.

Detection Content

Inspect the lithium battery case for appearance defects such as solder joints, warped nails, pinholes, bumps, pits, defects, scratches, dark blocks, rust, leakage, dirt, etc.

Application Solution

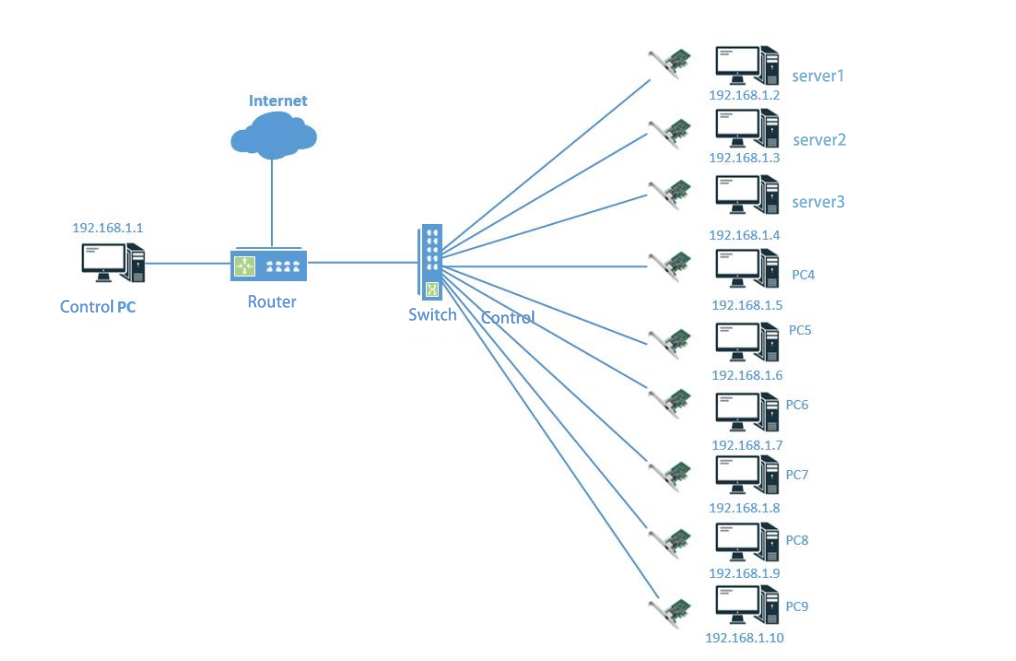

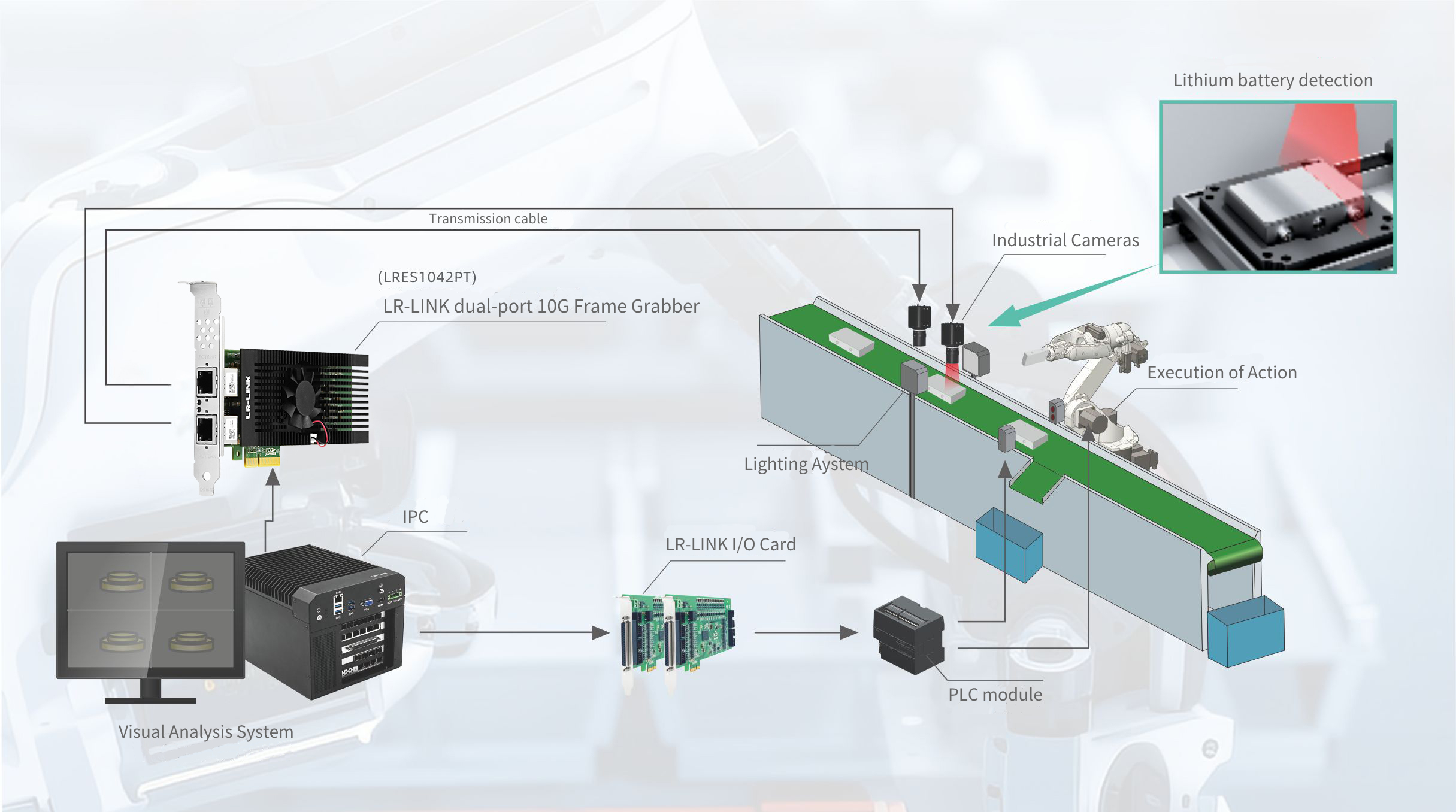

As a professional network card provider, LR-LINK has been deeply involved in the machine vision industry for more than ten years. In response to specific application problems, especially the frame loss problem, it independently developed a series of jumbo frame image capture cards that support 16348 bytes for machine vision. In the system, this problem can be improved from the frame grabber to facilitate efficient and high-quality inspection.

The frame grabber is used in machine vision systems. When detecting lithium batteries, it converts the analog signals of the lithium battery appearance images collected by the industrial cameras into digital signals and cuts, packages, and transmits these data to the computer to process and store. Compared with frame grabbers with 9014 bytes, the jumbo frame frame grabber supports jumbo frame transmission of 16348 bytes, reducing the number of frame cuts and data packets and avoiding congestion and frame loss during transmission process.

As the core key component of the machine vision system, the LR-LINK frame grabber has very high stability and reliability and is not easily affected by the external environment. It transmits each frame of lithium battery appearance defect image data collected by the industrial camera to the computer processing program completely, quickly and error-free, without missing any defect.

Solution Features

LRES1042PT supports 16348-byte jumbo frame transmission, which can reduce the number of frames, avoid congestion, and prevent frame loss.

·The transmission rate of each port is up to 10G, meeting the application requirements of large-capacity data transmission in high-speed networks.

·Supports MSI, MSI-L, LSO, RSS and IPv4/IPv6 checksum offloading to achieve high performance and low CPU usage.

·Compatible with mainstream camera brands, multiple interfaces can connect multiple industrial cameras stably.

·The performance is stable and reliable, not susceptible to environmental interference, and enables stable data interaction and transmission.

·The system has wide compatibility and meets the needs of diverse application scenarios.

LR-LINK jumbo frame grabber plays an important role in solving the frame loss problem during data transmission of lithium battery detection. It is an ideal machine vision frame grabber solution that helps improve the efficiency and quality of lithium battery detection and automates lithium battery production; moreover, it accelerates quality control upgrades.