In the last issue, we had a preliminary understanding of industrial cameras, transmission cables and frame grabbers. In this issue, we discuss the optimization setting steps of the 10G high-speed image acquisition card and the operating system, as well as the selection and configuration of the industrial computer.

Frame grabber optimization settings

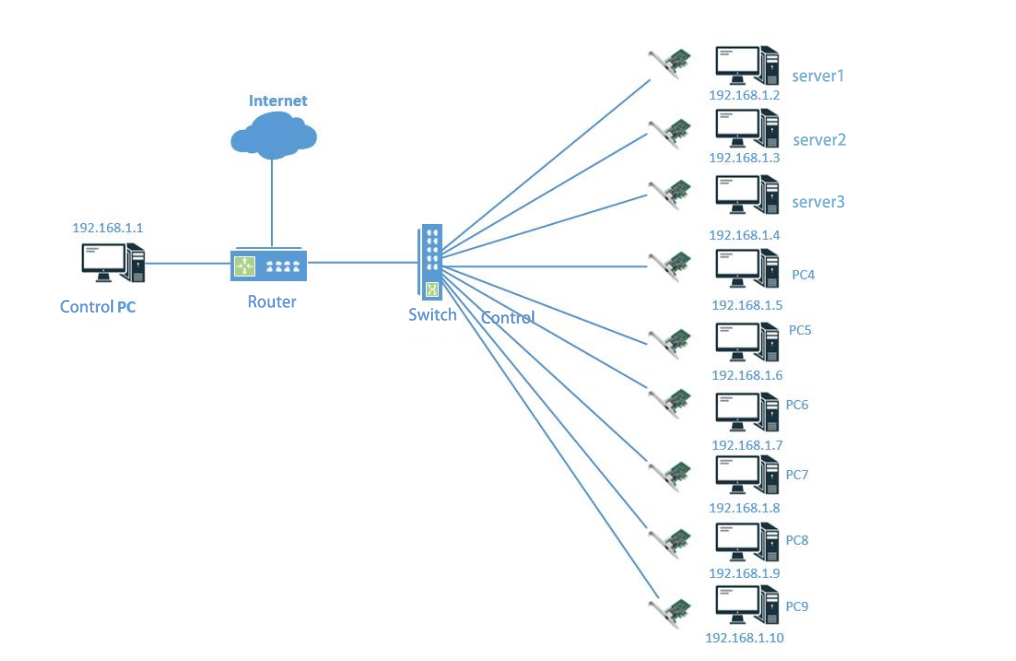

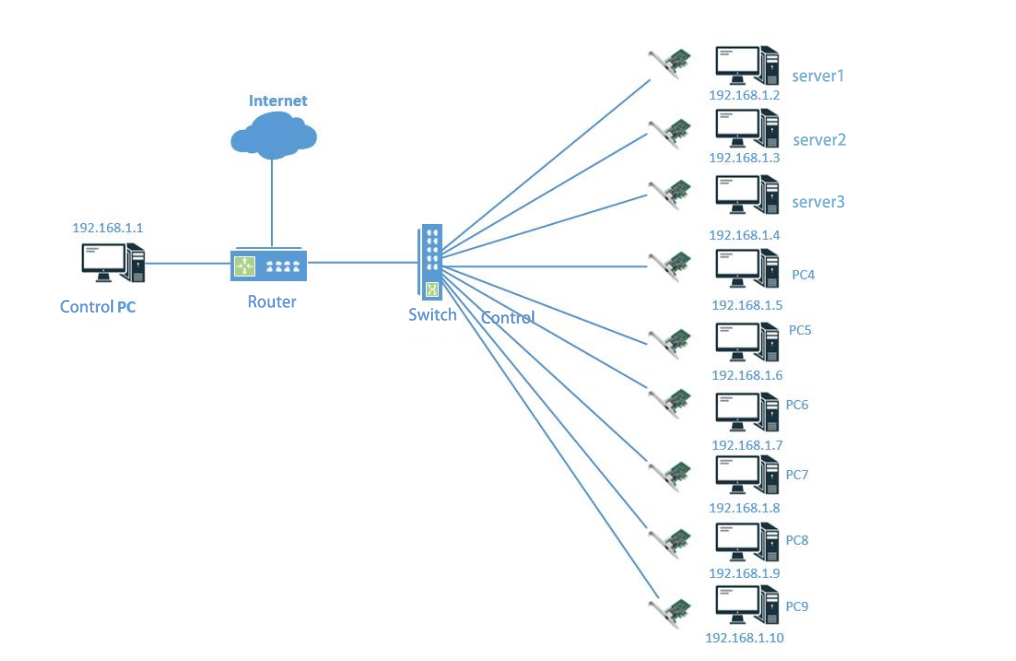

The frame grabber is a key component of the machine vision system. We can analyze its design routine items, such as network performance design, product thermal power, energy consumption, structure, etc., to ensure whether the product can achieve safe, stable, continuous and efficient operation at the user end. At the same time, optimize the settings of the image acquisition card. The general optimized items include jumbo data frame, transmission buffer, sending buffer, energy-saving Ethernet, flow control, DMA combination, etc. Depending on the products controlled by different brands, the driver will also have different names and setting items. For general settings, refer to the following figure.

In order to understand the operation steps more intuitively, we use LR-LINK 10G high-speed image acquisition card (brand model: LRES1042PT) for demonstration operation. First, after selecting the highest jumbo data frame "16348 bytes" in the "Advanced" column of the network properties, cancel the default checks of the two items "Allow the computer to turn off this device to save power (A)" and "Allow this device to wake up the computer (O)" in the "Power Management" column.

After optimizing all ports of the frame grabber, find "Power Options" from the "Control Panel", check "High Performance", and select "Never" in the "Turn off the display" and "Put the computer to sleep" options.

After performing the above operations, the optimization settings of the LR-LINK 10G high-speed image acquisition card are basically completed. Jumbo frame transmission is an important indicator of LR-LINK high-speed image acquisition card. The 16348-byte jumbo data frame can reduce the number of data packets in the network, reduce the extra overhead of network equipment processing packet headers, and effectively avoid frame loss.

In addition to the above optimized settings, the 10G high-speed image acquisition card needs to do a good job of heat dissipation to achieve continuous and stable operation. The LR-LINK 10G image acquisition card adopts a high-efficiency radiator, which can dissipate heat in time to ensure the continuous and stable operation of the image acquisition card in the industrial computer.

OS optimization

It should be noted that after using the industrial camera of the TCP protocol, the operating system must be optimized, and the network can be optimized by turning off the "receiving window automatic adjustment level". The operation steps are as follows:

Execute CMD as an administrator, and enter the execution command: netsh interface tcp show global; you can see that the current "receive window automatic adjustment level" parameter is the default state of "normal".

By executing the command: netsh int tcp set global autotuninglevel=disabled, modify it to "disabled".

Industrial computer selection and configuration

In order to better realize 10G image acquisition and data transmission, in addition to optimizing the settings of the image acquisition card, the selection and configuration of the industrial computer is also important. It is recommended to give priority to the type of industrial control motherboard designed for industrial control. Because most devices simultaneously process the collected image information and perform the next operation while performing the image collection work, especially the need to upload the image to a dedicated server. Therefore, the industrial computer in such multi-dimensional work needs more hardware resource support.

When selecting a model, usually strengthen the corresponding configuration according to the number of connected industrial cameras. If a single 10G industrial camera is used, it is recommended that the industrial computer choose the following configuration:

OS: Windows 10 (Windows 11) x64 Professional Edition

CPU: 10th generation i7 or above

DDR: above 16G

SSD: more than 128G

Summarize

After completing all the above operations, the industrial computer, 10G high-speed image acquisition card, industrial camera, etc. can be reasonably optimized to avoid abnormalities such as frame loss, disconnection, and downtime.

As 10G is a major trend in the development of machine vision, it is particularly important to choose professional manufacturers when selecting and matching equipment such as image acquisition cards and connecting cables. LR-LINK has been deeply involved in the machine vision industry for many years, and has been at the forefront of the industry in the development of image acquisition cards. It has achieved 60% industry coverage, 70% of customers repurchase, and 80% industrial camera adaptation. It also provides one-stop procurement services for image acquisition cards and high-quality connection cables. It solves problems such as frame loss, packet loss, and disconnection to a greater extent, and empowers the machine vision industry to develop towards intelligence and refinement.