According to statistics, 83% of the information that humans obtain from the outside world comes from the eyes. Vision is an important way for humans to observe and understand the world. Industrial automation also needs a pair of "wisdom eyes" to help machines "understand the world". As a key technology to realize industrial automation and intelligence, machine vision is a branch of artificial intelligence with the fastest development and broad prospects. Its importance is just like the value of eyes to people.

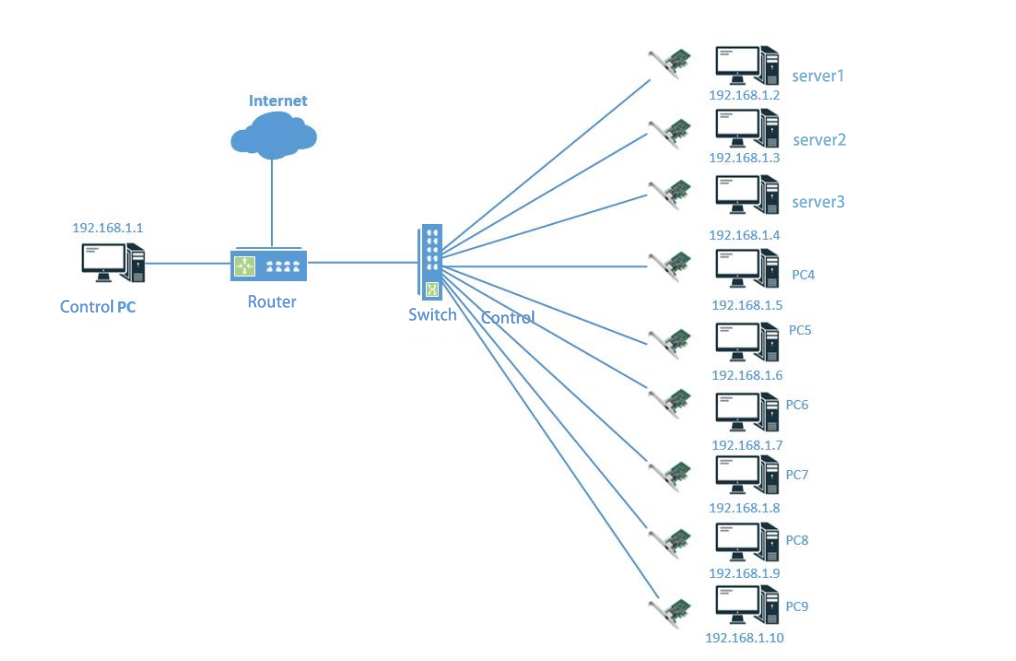

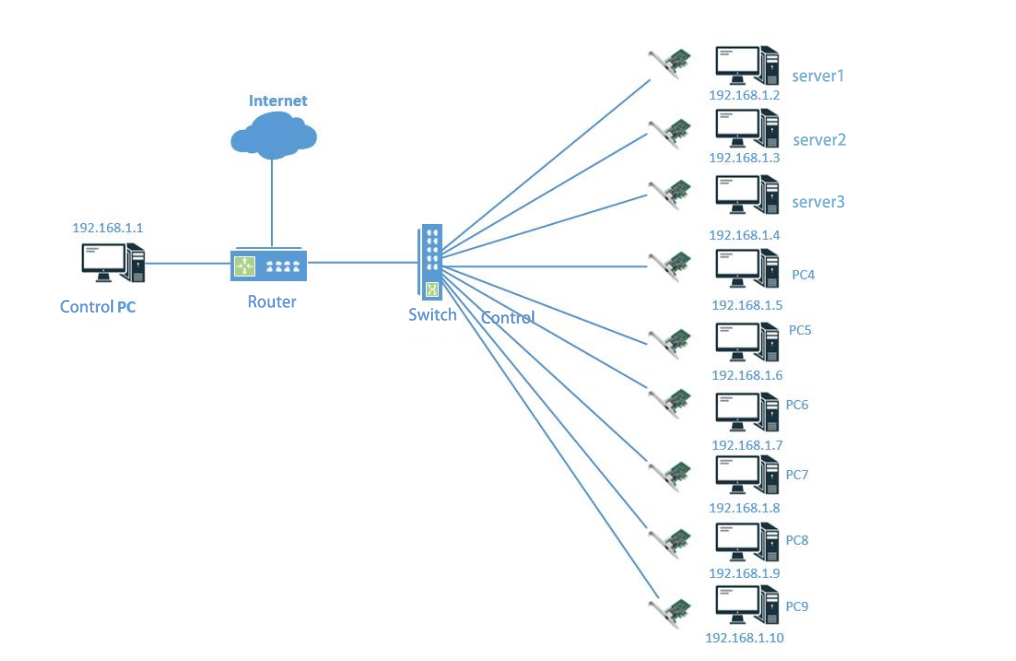

According to the definition of the Society of Manufacturing Engineers (SME): Machine vision is the use of optical non-contact sensing devices to automatically receive and interpret images of real scenes to obtain information to control machines or processes. It is mainly composed of light source, lens, industrial camera, image acquisition card, image processing system and other external equipment. In short, machine vision is to use machines instead of human eyes to observe, measure and judge things. It is known as the "eye of industry" and is mainly used in photovoltaics, new energy, semiconductors, rail transit, smart medical care and other industries.

After 30 years of development in China, the market size of machine vision in China has reached 13.816 billion yuan by 2021, and it is expected to increase to 60 billion yuan in 2026. However, behind the exponential growth of the market size, users usually face problems such as loss of image information, abnormal data transmission, and poor compatibility of software and hardware in applications.

· In data acquisition, transmission and processing, due to factors such as insufficient industrial camera buffer, unstable image acquisition card performance, or unsupported visual software programs, image acquisition is incomplete and data transmission is unstable, resulting in frame loss.

· The data transmission process is affected by transmission bandwidth limitation or network congestion, resulting in abnormalities such as noise or blurring of image data, and information that cannot be detected and fed back in real time, affecting the stability and fluency of data transmission.

· Poor compatibility of equipment such as industrial cameras or image acquisition cards will make them unable to fully exert their performance, and the performance of algorithm software will also decline or make mistakes, which will affect the normal operation of the machine vision system.

At present, global machine vision is growing explosively. Although China's machine vision started late, its growth rate is much faster than that of the world. Therefore, enterprises in the machine vision industry can follow the general trend of industrial "smart" manufacturing, jointly explore solutions and innovative technologies, improve the performance, stability and reliability of machine vision systems, and help intelligent manufacturing enter the era of Industry 4.0.