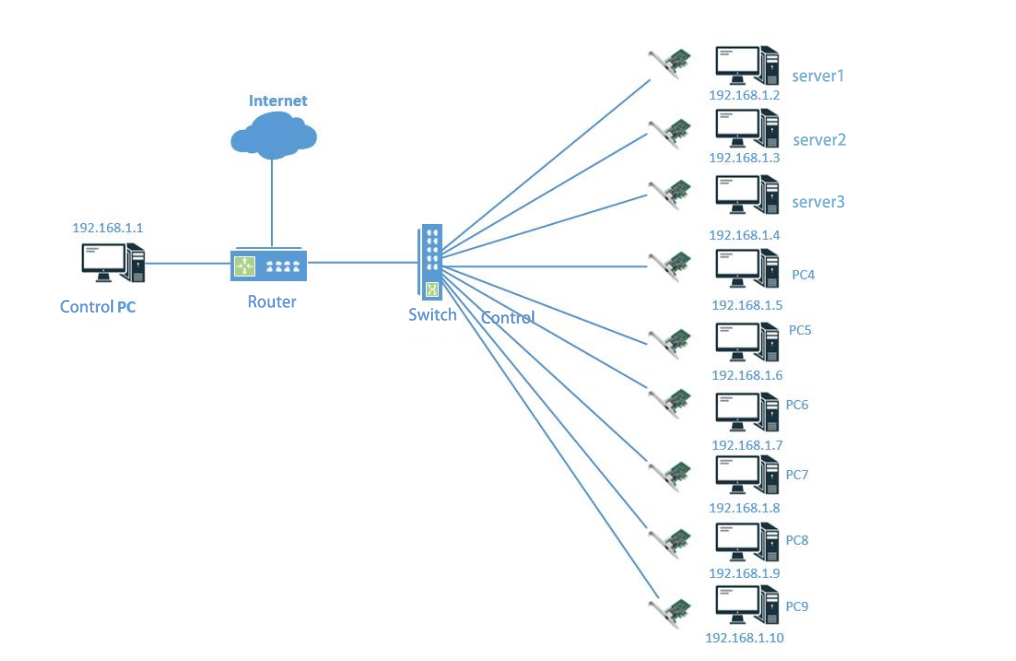

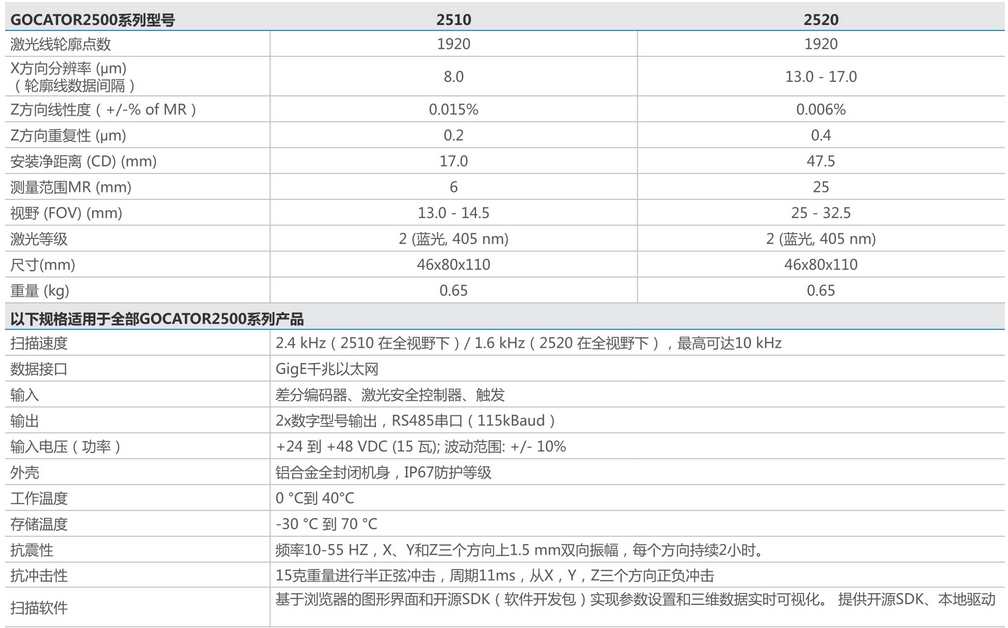

"I used this cassette LMI (LMI Technologies) line laser, eight in one project, 12 in one." LR-Link network card products are used in 3D laser scanning projects.

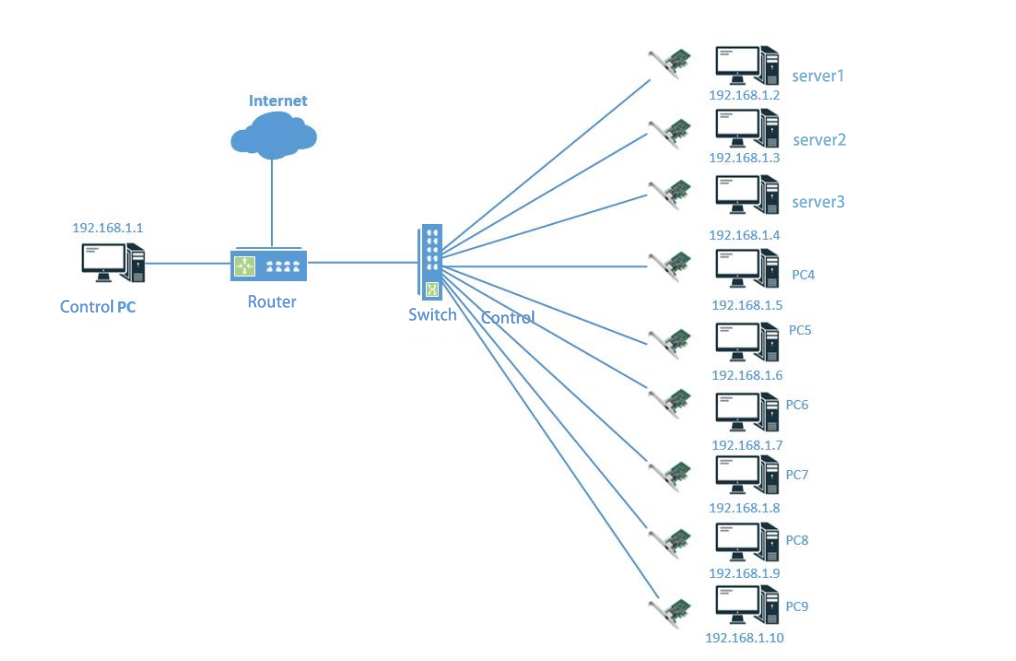

Network card products used in laser scanning projects can be used for the automotive industry of air conditioning unit assembly, condenser, electric fans, radiators and other 3D scanning detection; And like all kinds of products surface reconstruction, A level surface treatment, 3 d modeling, mechanical design, clay model digitization, tools and fixture development, maintenance, repair and overhaul (MR0), finite element analysis (FEA), scanning the existing object, the 3 d file, medical applications, complex shape acquisition, measurement, archiving, damage assessment, digital model and entity model, packaging design, and fast Speed molding, etc.; Or compare parts with designs, or achieve high-performance 3D laser scanning of railway tracks, etc.

Compared with conventional detection methods, 3D laser scanning has the following advantages:

High resolution: Detect every detail and provide extremely high resolution;

1. Extremely high precision: to provide incomparable high precision, real-time generation of precise 3D object images;

2. Automatic multi-resolution: some new batch triangulation processing devices can maintain higher resolution when needed, while maintaining a larger triangular mesh in the plane;

3. One-to-one dual scanning mode: Some new scanning modes support users to switch between regular and high-resolution scanning modes. Conventional resolution is suitable for large parts and dynamic scanning, while high-resolution is dedicated to complex surfaces with strict requirements.

4. Self-positioning: No additional tracking or positioning equipment is required. The positioning target technology allows users to move the measured object in any way and from any Angle according to their needs.

5. Portable: it can be loaded into a suitcase and carried to the operation site or transferred between factories;

6. Affordable price: no need for other external tracking devices, and very low maintenance costs;

7. Powerful, user-friendly: even in a small space can be used easily, can scan any size, shape and color of the object.

3D laser scanning obtains contour data of products through optical non-contact scanning, and transmits the data to each computer work unit in real time to complete data acquisition; Decisions can also be passed to the production control unit for on-line adjustment.

(3D scanning is applied to production schematics. The picture is from the Internet)

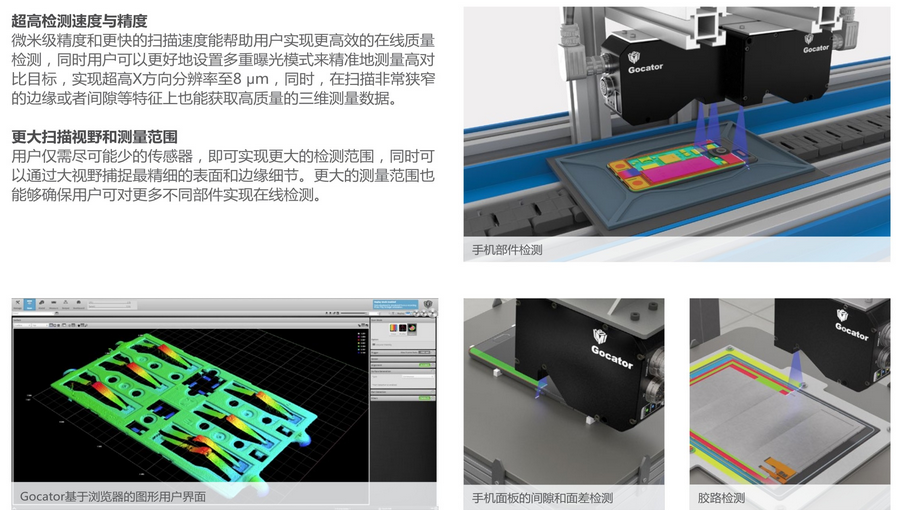

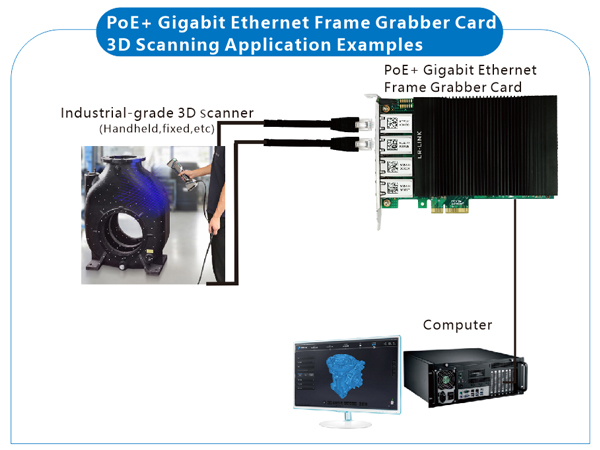

(Laser scanner can be linked to GigE Gigabit network card use. The picture is from the Internet)

(Car profile scanning with high reflective surface scanning. The picture is from the Internet)

Laser scanning has the unique advantage of being able to scan specular and diffuse surfaces at the same time. For example, accurate 3D scanning of glass and other planes is carried out to detect key assembly data. Can handle a wider range of surface angles, material types and surface colors to achieve high-speed, reliable and high quality data.

The 3D scanner directly transmits data to the computer in real time through the POE + Gigabit Ethernet network card installed on the computer for computing output.

The emergence of multi-type transmission rate LR-Link Link network card and POE powered network card products, a great solution to the popularity of laser 3D scanning application, for the development of high speed and high quality of the real industry add tile power.