"I changed all the mining machines in the project into your PoE network card and camera combination, and the operation efficiency was improved tens of times, which saved me a lot of money," said a customer engaged in the intelligent ore sorting field to the business personnel of LR-LINK.

Intelligent ore sorting system is a kind of using machine vision and deep learning, such as automatic control technology, combined the technology of high performance computing and big data, simulate the human eye and brain, through different spectral imaging, analysis of the corrosion on the surface of the ore into color, texture, etc., and quantitative analysis of ore for quickly and accurately and effectively chosen intelligent automatic ore sorting equipment. It is also a fully automated intelligent equipment system gradually emerging in recent years.

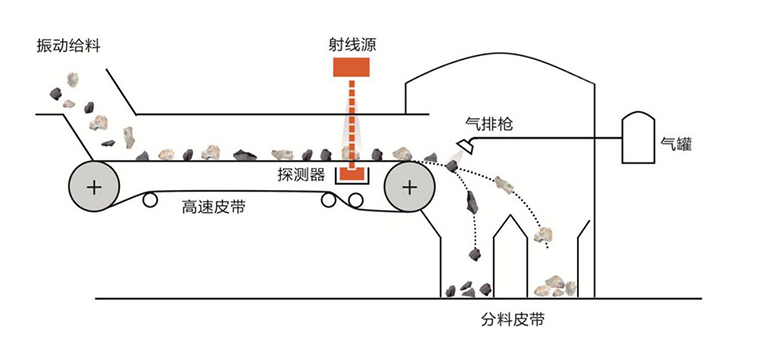

Intelligent ore sorting system is composed of three core technologies: machine vision, big data computing and deep learning. The main working principles of equipment sorting are as follows: The upper end of the equipment is fed by vibration, and the ore raw material is transmitted to the detector through the high-speed belt. At this time, the ray source located above is based on dual-energy X-ray fluoroscopy and material identification, and carries out all-round acquisition and scanning of the ore (machine vision detection technology), and transmits the obtained data to the computing end through Ethernet. Then the computer by the high performance computing to detect target direction, multi-angle, multi-level feature extraction and data fusion, finally comprehensively and precisely describe the inherent characteristics of detecting target, and the results back to the customer after processing, and issue instructions specified end, gas volley final action of ore sorting according to the instructions.

(Image from the Internet)

System performance advantages of intelligent ore sorting equipment:

Anyway intelligent: Sorting stands for intelligent control and remote operation without human intervention.

Agreeing something, they are highly accurate: a combination of advanced technologies, including multidimensional detection and X-rays, allows them to identify the ore and waste rock with precision.

They are efficient: the ore machine has a daily sorting capacity of up to 200t/ H.

Compared with traditional manual ore sorting, it has the advantages of higher accuracy, higher efficiency, higher output and lower operating cost. It has been widely used in ore enterprises such as concentrator, quarry, slag and stone dump and metallurgical enterprises which use metallurgical production waste sorting.